This post was published to

Avoiding the Corporate Deat... at 7:22:51 AM 6/23/2018

Energy Companies Need to Stop Worrying About Oil

Prices

“It is not enough to do your best. You

must know what to do, and then do your best.”

– W. Edwards Deming

If recent history is any indication,

energy companies expecting to survive in the years ahead are going to have to

adopt a new business philosophy. As is the case with any commodity

producer, market price is a factor for financial success. The problem, though,

is that many companies have come to rely on it as the only factor and, as a

result, surrendered the ability to control their own fate. While crude prices

are contributors to financial success, they do not have to be the only factor

in determining whether a producer is profitable or not. What is needed is

a new business model – one that enables companies to produce oil responsibly

and profitably whether prices are $70 or $30. If an energy company cannot

figure out how to remain profitable in a world of wide swings in oil prices, it

may as well find something else to do because its future, if it has one, is

going to be severely compromised.

As companies in other industries

have discovered over the years, a business model guided by lean thinking can

help secure a future in a world of unpredictable and widely variable market

conditions. Although the acceptance of lean in the energy industry has

increased over the last several years, there is still significant

misunderstanding about the need for transformation in order to achieve the

level of success that organizations in other industries have

experienced. After several years of failed attempts to achieve

improvements through tools-focused approaches like 6-sigma – where improvement

methods are placed within existing systems and the responsibility for solving

problems is delegated – some organizations are starting to understand the need

to apply a new philosophy that integrates improvement at all levels of the

business in order to achieve the big gains that are possible in safety,

environmental performance, production, and cost.

The industry is still in its infancy

in understanding and applying lean to the point where it will reduce its

addiction to oil price. When accompanied by true and fundamental

transformation, lean can help an energy company take full advantage of the

periods of high prices while preparing for the inevitable drops without feeling

the need to implement drastic measures that damage long-term health.

COPYING DOESN'T WORK

Applying lean to an oil and gas

producer, as with any company, requires a clear understanding of the philosophy

rather than attempting to copy how Toyota – or anyone else – does

it. Copying drives a focus on the tools and ignores what you can’t see –

the fundamental changes in the company's systems (e.g., leadership, hiring,

training & development, promotions, etc.) that are necessary for

success. For years, though, Toyota provided the only real example of what

many now refer to as lean, and those wanting to learn approached the deployment by

rolling out tools like kanban, 5S, or value stream mapping. The problem

is, without a clear understanding of lean as a system that requires

transformation in the way the organization operates, the best one can expect is

random improvements that are difficult, if not impossible, to sustain.

When people begin to truly

understand lean, including systems thinking, psychology, and the application of

the Plan-Do-Study-Act (PDSA) cycle, they begin to approach work differently,

and become much more focused on what's truly important to the

organization. The way people think about problems shifts and the

organization starts to replace the traditionally overly complex, gut-feel, boss-knows-everything approach with a simpler, more scientific way of operating.

In the most basic terms, lean is

about:

- Having clear standards based on the needs of the

business;

- Following standardized work that enables the standards

to be met;

- Quickly identifying when a standard cannot be met (i.e.,

when a problem occurs);

- Identifying and addressing the causes for not meeting

standards (problem-solving);

- Knowing when a standard needs to be improved and having

a method for doing it.

Although it sounds simple, making

the above work effectively requires transformation in many of the company's

systems as well as its culture. When a company ignores the signs that its

systems or culture are interfering with improvement, lean becomes a burden and

is seen by many as a waste of time.

WHAT TO DO

Once people in the industry begin to

understand and appreciate the various aspects of lean, including a focus on

continual learning and the connection to the organization's fundamental

purpose, things will start to change. The thinking that drove improvements

at Toyota like reducing setup times on stamping presses from 3 hours to 3

minutes or completely eliminating wasted paint during the body painting

operation while reducing color changeovers to seconds, can help contribute to

greatly reducing an oil producer's cost per barrel, shortening its lead time

from exploration to first oil, and significantly reducing emissions while

improving safety. It won't necessarily happen in one year or even two, but

the improvements along the way will show the potential of a culture that is

aligned and improvement-focused throughout the organization.

Some of the keys to assuring the

successful application of lean to an energy company include the following:

- Leaders must

understand and actively drive, rather than delegate, the transformation. To

do this, they must be taught what to do, be open to coaching, and accept

the responsibility of creating a culture obsessed with improvement;

- Establishing a culture where continual learning and development

is highly valued and expected of every team member from the newest hire to

the CEO; and holding leaders responsible for coaching and developing those

on their teams;

- Developing a clear and consistent

purpose (i.e., the mission and vision) for the organization –

and staying true to the mission while ensuring that all activities are

oriented toward achieving the vision, including helping everyone

understand how the work they do connects to the purpose;

- Designing systems that enable problems to be shown quickly and

clearly, and ensuring people feel comfortable showing the problems in

their areas. Any area or team that does not have problems only means

that they are not being shown, which is likely caused by cultural reasons;

- Ensuring a single clear and

consistent approach to lean. Do not allow alternate training or

tools to come into the organization unless it is driven by, and clearly

connected to, the deployment. Do not let anyone add confusion by

introducing new tools or methods that do not fit within the standard

approach.

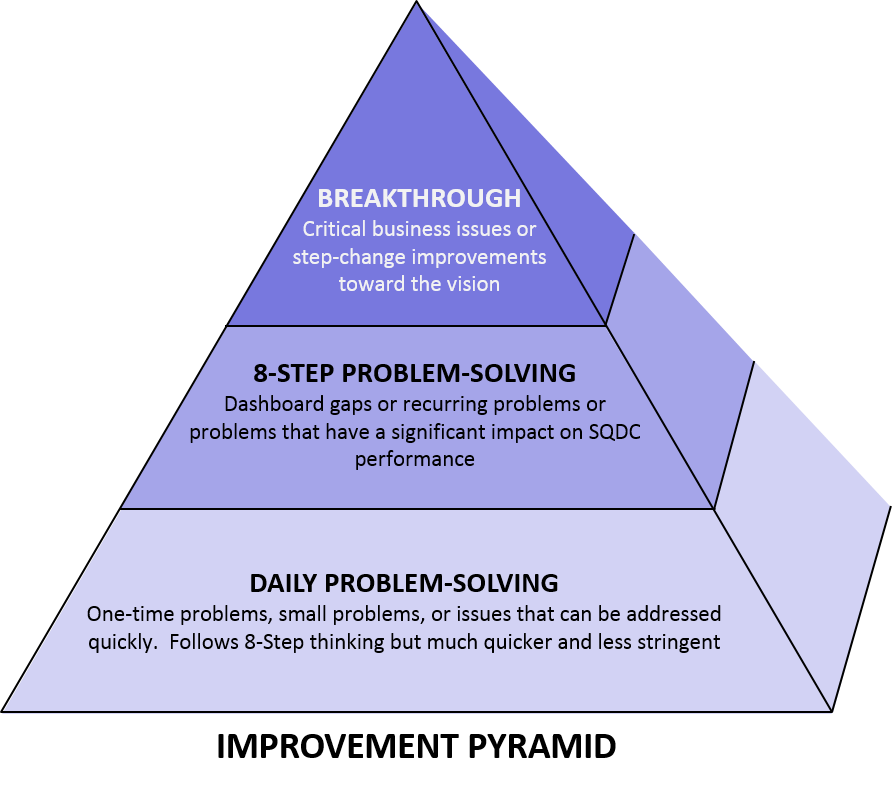

When deployed correctly, lean

entails a vastly different approach than most people are capable of

understanding at first. Through real-world practice, effective coaching,

commitment, and patience, people will start to understand and see the big gains

that are possible through an effective transformation. As the organization

starts to unleash the talents of its people through the combination of daily

problem-solving and breakthrough thinking, the ability to create an

organization that improves profitability by producing energy safely, cheaply,

and responsibly regardless of the price of oil will become a reality, and

rather than blank stares, eye-rolling, or resistance when concepts like perfect

safety, drastically shortened lead times, or zero emissions are presented,

people will become energized and focused on making them happen.