Why have so few organizations been truly successful with lean? The philosophy has been around in one form or another for many years and there is no shortage of books, papers, and seminars on the subject. Even with well-publicized examples like Toyota, Southwest Airlines, and Herman Miller, the probability that a lean deployment will succeed today is fairly low.

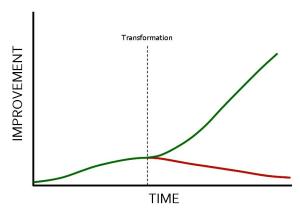

A major factor contributing to the problem I have found is that people tend to underestimate the transformation required to succeed. When one learns about lean, there is a tendency to believe that teaching people how to identify and eliminate waste is the key to success. Although there is a fairly good chance that improvement will occur after investing in training and coaching, without transformation the organization will never get beyond the initial stages of lean and never realize the big gains that can be achieved through its adoption. The pace of improvement will eventually slow, and the resulting frustration and natural pull back to traditional thinking will eventually lead to abandoning the effort.

Transformation in Thinking

There is a point in the process where a significant transformation in thinking is needed to move the organization to the next level and achieve the big gains. Whether occurring at a single point or several points over time, transformation in thinking occurs when leaders begin to realize that the organization's problems are the result of barriers that only they can fix. It is at this point when workers are no longer blamed for poor performance and the lack of improvement.

Although necessary for improvement, lower level kaizen activity can only take the organization's performance so far, while addressing issues like poor hiring and promotion systems, an unclear or inconsistent purpose, a lack of learning, ineffective planning, and other barriers are the way to tap into the 94% of the improvement opportunities available to the organization.

What causes a leader to transform his or her thinking depends on experiences, perspectives, and outlook for the future – and it’s different for everybody. The key to success is to keep working with people until they realize lean is a very different approach to business. It requires a dedication to lifelong learning and change, and the understanding that the inertia associated with the traditional approach to business will cause a continual pull within the organization back to its old ways.

No comments:

Post a Comment