One of the most common frustrations expressed by those involved in a 6-sigma journey is the inability to get others to participate in improvement activities. In some cases, energy levels may be high during initial projects only to have a production focus return fairly quickly. Often there is less accountability for process improvement than meeting production targets, and it becomes a battle to get managers to commit time and resources to improvement projects.

The Wrong Focus

A common reason for a lack of managerial engagement in improvement activities stems from the lack of a natural alignment between improvement objectives and a manager’s normal work – i.e., meeting production targets (production referring to any type of output for which a team is responsible). As long as improvement objectives are considered separate from production objectives, there will always be tension between the two; and when this happens, production will virtually always win.

Production is how a company makes its money, and managers are typically measured on their ability to produce. No matter how logical it may seem so some that focusing on improvement will make meeting production targets easier, others will see it as a distraction and interference to meeting production objectives.

By design, a 6-sigma process is project focused, where people identify improvement opportunities, develop objectives, and form teams to address the issues. This approach can make the job of creating and sustaining alignment between improvement and production a challenge.

Although some companies have been successful implementing and sustaining project-focused improvement, many have not. In my experience, the life of a typical 6-sigma deployment is 6 months to one year. Beyond the initial success, a lot of time and energy is required to keep the process going against the inertia of a production focus.

A Better Approach

A much better way to create a strong and natural alignment between improvement and production is to focus the effort on lean rather than 6-sigma. Companies that ignore lean and attempt to implement an isolated 6-sigma process are missing out on a perfect opportunity to connect and closely align production control and the improvement process. With lean, it is takt time that makes the need for continual improvement clear and logical.

Takt time, which can be calculated for virtually any process in any industry, defines the pace at which a process needs to operate in order to meet objectives. Once the output objectives and resource constraints are understood, the takt time of the process can be calculated with little effort.

Understanding the takt time for a process makes it clear that, in order to meet production targets effectively, improvement efforts must occur. This approach places the responsibility for initiating improvement projects with the supervisor of a process since he or she is the one accountable for consistently meeting production - or takt time - targets. In effect, takt time creates pull from those directly involved in the operation.

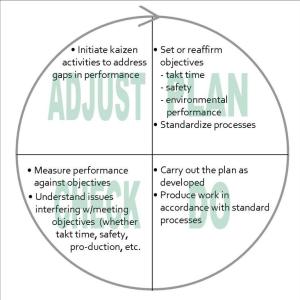

The PDCA diagram below identifies a basic approach for implementing and sustaining improvement-based on lean thinking. Once business objectives are understood and processes are standardized, process leaders become responsible for meeting production objectives on a continual basis. Unless the person responsible for leading a particular process drives improvement within his or her area of responsibility, the odds of meeting takt time consistently become severely hampered. Continually comparing throughput to takt time naturally drives the identification of improvement projects that enables objectives to be met.

To be successful in a lean thinking environment, very little pressure is placed on people for the current performance of the process(es) they lead. There is significant pressure, however, on leaders to demonstrate how they are reacting to current performance, and the steps they are taking to drive improvement.

Every leader must be held accountable for assuring that the overall system (i.e., production line, location, business unit, etc.) meets its takt time. Otherwise, improvement efforts may consist of pushing work or inventory to a downstream process, and when this occurs, there is little chance for the organization to meet its objectives.

No comments:

Post a Comment